15-07-2023

15-07-2023- Blog

- 0 comments

- 3861 Views

Concrete and timber subfloors are two common types of subfloor materials used in flooring installations. Here's a comparison between the two:

-

Material and Construction:

- Concrete Subfloors: Concrete subfloors are made of a mixture of cement, aggregates, and water. They are typically poured and leveled to create a solid, durable surface for flooring installation.

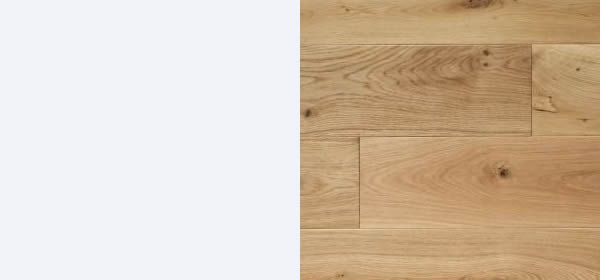

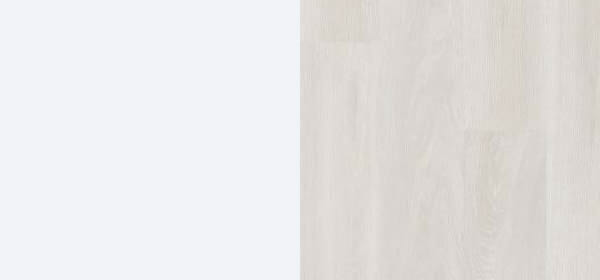

- Timber Subfloors: Timber subfloors are constructed using wooden joists or plywood sheets. The joists provide structural support, while the plywood sheets create a stable surface for flooring installation.

- Concrete Subfloors: Concrete subfloors are made of a mixture of cement, aggregates, and water. They are typically poured and leveled to create a solid, durable surface for flooring installation.

-

Stability and Durability:

- Concrete Subfloors: Concrete is known for its stability and durability. It offers a strong, long-lasting base for flooring materials, making it suitable for high-traffic areas and heavy loads.

- Timber Subfloors: Timber subfloors can also provide good stability, especially when constructed with proper joist spacing and adequate support. However, they may be more prone to damage from moisture, pests, or movement over time compared to concrete.

- Concrete Subfloors: Concrete is known for its stability and durability. It offers a strong, long-lasting base for flooring materials, making it suitable for high-traffic areas and heavy loads.

-

Moisture Resistance:

- Concrete Subfloors: Concrete is inherently moisture-resistant, making it suitable for areas with high humidity, such as basements or bathrooms. However, concrete can still absorb moisture if not properly sealed or if cracks develop.

- Timber Subfloors: Timber subfloors are more susceptible to moisture damage. They can warp, swell, or rot when exposed to excessive moisture, which may require additional measures such as vapor barriers or moisture mitigation systems.

- Concrete Subfloors: Concrete is inherently moisture-resistant, making it suitable for areas with high humidity, such as basements or bathrooms. However, concrete can still absorb moisture if not properly sealed or if cracks develop.

-

Installation and Flexibility:

- Concrete Subfloors: Concrete subfloors require professional installation, as they need to be properly poured, leveled, and cured. Once installed, they provide a rigid surface that is compatible with various flooring materials, such as tile, vinyl, or carpet.

- Timber Subfloors: Timber subfloors offer more flexibility in terms of installation. They can be constructed on-site or pre-manufactured as panels. Timber subfloors are well-suited for nail-down or glue-down installations and are compatible with a wide range of flooring materials.

- Concrete Subfloors: Concrete subfloors require professional installation, as they need to be properly poured, leveled, and cured. Once installed, they provide a rigid surface that is compatible with various flooring materials, such as tile, vinyl, or carpet.

-

Thermal Insulation:

- Concrete Subfloors: Concrete is not a good thermal insulator and can feel cold to the touch. Additional measures, such as installing insulation under the subfloor or using radiant heating systems, may be necessary to improve thermal comfort.

- Timber Subfloors: Timber subfloors offer natural insulation properties, providing better thermal comfort underfoot. Timber has inherent warmth, which can make it more comfortable in colder climates.

- Concrete Subfloors: Concrete is not a good thermal insulator and can feel cold to the touch. Additional measures, such as installing insulation under the subfloor or using radiant heating systems, may be necessary to improve thermal comfort.

Ultimately, the choice between concrete and timber subfloors depends on various factors, including the specific requirements of the space, the desired flooring material, and considerations such as moisture, insulation, and structural support. It's important to consult with professionals and follow recommended practices to ensure proper installation and long-term performance of the chosen subfloor material.

Recent Comments

No Comments have been left yet! Be the first :)